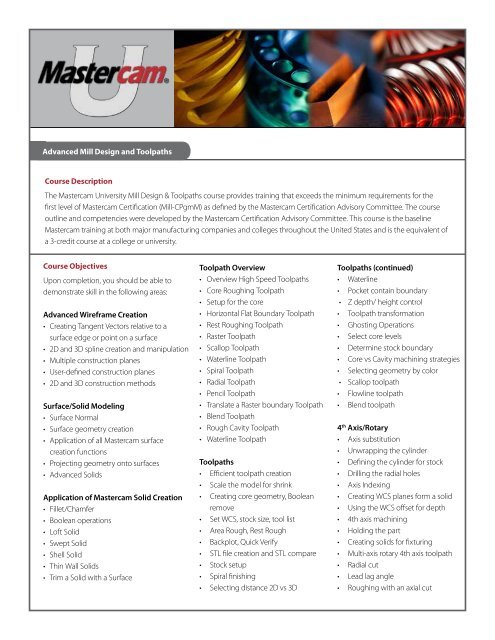

MasterCAM 2020 Reference > Assigning Geometry What is a Roughing Operation?Ī roughing operation is used to remove large amounts of material rapidly and to produce a part geometry close to the desired shape. MasterCAM 2020 Reference > Managing Operations Plastics (Acrylic, HDPE, Corian, Pattern Board).Non-ferrous metals (aluminum, brass, copper).The GSD FabLab does not currently provide templates for less frequently machined materials, though we do maintain tooling to work with the following: Wood Flat Stock 2D Milling Template - With Sample Geometry (2020) Wood Context Model Milling Template - With Sample Geometry (2020) Wood Context Model Milling Template - Without Sample Geometry (2020) A special template is provided for milling flat stock materials, such as single sheets of plywood or MDF. The wood template should be used for all wood and wood products, including softwoods, hardwoods, plywood, oriented strand board, and medium density fiberboard.

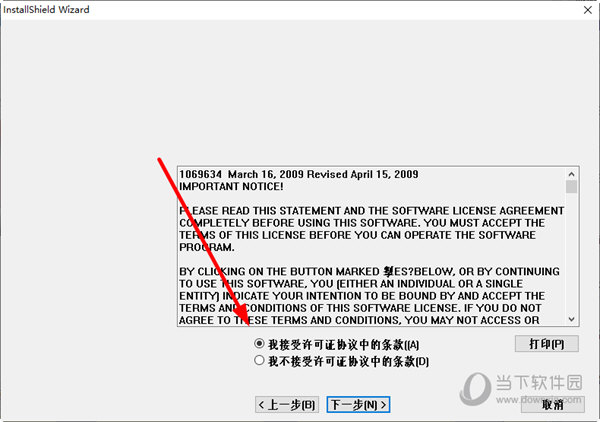

Define stock size (must match physical material to be milled).Verify location of geometry relative to file origin.Open template file (material appropriate).The FabLab has created material-specific MasterCAM template files to help alleviate common setup issues.Ī basic workflow for successful MasterCAM setup is as follows: Staff and TA's are not available to set up users' files for them. This page will enumerate the steps required to have an approvable MasterCAM files. CNC TA's are available during regular daily hours throughout the semester to answer questions, review submitted files, and run approved files on the mill. In order to use the large bed CNC routers at the GSD, students must submit a MasterCAM file to the online queue with geometry imported and operations assigned. Please use this page in conjunction with the MasterCAM 2020 Reference.

0 kommentar(er)

0 kommentar(er)